|

Upgrades

and choices Standards

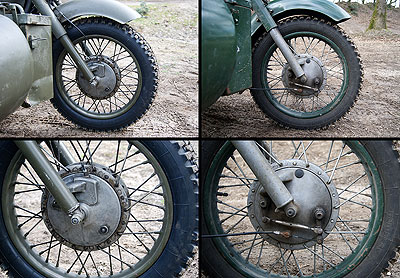

We build all our BestBear sidecars with

a two-leading-shoe front brake for the best result when braking

becomes essential.

Front brakes: single-leading

shoe brake versus two-leading shoe brake

Engines and drive-line components

We also offer choice in our upgraded

engines; the 750cc flathead or the 650cc KMZ 650 over-head-valve

type and/or an upgraded gearbox.

Rear drive units we can supply, with or without differential

locking device, are upgraded with European quality bearings

and oilseals.

If you want to convert your own non-driven KMZ Dnepr sidecar

combination or solo Dnepr motorcycle to a driven sidecar combination,

we can provide you with the complete driveline and sidecar

chassis needed to build the vehicle yourself, if prefered

including a military or civil type sidecar body. These driveline

components are as a matter of course also upgraded to our

European quality standards.

Options

Shockabsorbers: although the standard

Russian made shockabsorbers are of adequate design, overhaulable

and usually up to the job, they do not give the most comfortable

ride under all circumstances.

Therefore we offer a choice of several possibilities to upgrade

in springs and damperbodies.

The simpliest way is a Russian damperbody,

non-adjustable and with modified dampercharacteristics, equipped

with a progressive spring of the Dutch make Koni (nowadays

Ikon) mounted on the sidecar. This will already make life

a lot easier for the sidecar passenger and will give a less

bumpy ride when the sidecar is empty. This option is also

available as a complete shockabsorber and spring unit with

adjustable rebound-damping of the high-quality make Koni’s

7610 series, modified by us to fit to the Russian attachment

method.

If you want the very best of all we can provide you with a

set of three modified Koni shockabsorber units, each specially

adapted to their own purpose. For the sidecar this consists

of the Koni mentioned above, accompanied by two Koni shockabsorbers

for the rear end of the motorcycle, which can be equipped

with a variety of different springs according to the riders

preference. This will smoothen out bumps and potholes other

makes cannot cope with, while at the same time road stability

will benefit a great deal. The Koni shockabsorbers supplied

by us will be equipped with green or dark grey impregnated

canvas covers to keep the dirt away, thus extending service

life.

As an alternative we can also fit specially

adapted British made Hagon shockabsorbers with metal covers

over their progressive springs, either one for the sidecar

or a set of three for the whole combination.

The big advantage of the upgrade with Koni’s, besides

the adjustable rebound-damping, is the fact that these are

overhaulable while the Hagons are not. Ikon from Australia

still produces all spare parts for these Koni’s at reasonable

prices.

If parts are not up to the BestBear

standards we replace those.

|

|

Accessories

Besides the standard military equipment

which we usually supply our vehicles with - a 10 litres jerrycan

in holder, one ammunition box, machinegun holders fore and

aft plus a large spade and axe - we can also deliver the original

stand for the Diegtiarev DP28 machine gun.

Other accessories are a wooden floor in the sidecar body,

extra ammo-box and sheet metal leg shields. We can also offer

you the original bakelite emergency light, fitted with a led

bulb, and the original Russian black-out device for the headlight,

if you wish so mounted with a reflector for the standard Russian

or 6V 25W halogen bulb. Caution: in some countries this may

not be road-legal.

Although the entire production made in Kiev for the Soviet

Army was of fairly good quality, we found some typical material

flaws to iron out as well as a couple of parts for which there

are far better alternatives available in West European quality.

BestBear upgrades

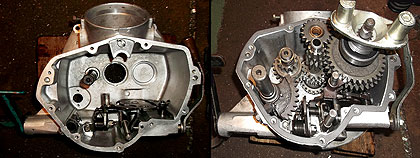

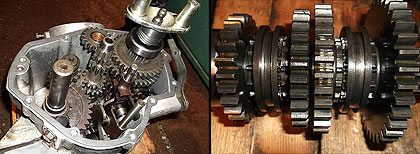

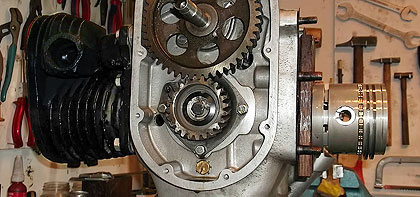

Our upgrades include amongst others a

better oilpump and recalibration of the oil distribution throughout

the entire engine, better air filtration, German made piston

rings, better exhaust valves and reworking of the inlet and

exhaust ports, static counter-balancing of pistons and small-ends

within less than 1 gramme tolerance and better (asbestos-free)

clutchplates. Contact points, ignition coil, bearings and

oil seals are also replaced by West European quality parts.

With these modifications our engines

are very reliable and smoothly running, also due to the fact

that every single part is checked and if only doubtful replaced

before we put the engine together again in a well equiped

non-production workshop: one man builds one engine at the

time, not hastened by production targets. Quality of workmanship

is what counts. Quite the opposite of former Eastern-Block

production philosophy you might say...

Weighing out and adjusting in a lathe of the pistons.

Recommendations

The OHV engines can do with a good 20W50

multigrade engine oil all year round.

In the flathead engines we strongly advise

the use of a good quality single grade engine oil, e.g. Quaker

State SAE 50 under normal conditions and SAE 30 in cold climate

(below 35 F).

For the gearbox a good quality EP 80-90

gear oil GL4 or GL5 will do the job.

The rear drive and differential unit and the sidecar drivebox

are best lubricated with Castrol SAF X-J differential oil.

The front fork works best with 0.13 l SAE 10 damping oil in

each leg.

Do not convert by Bestbear upgraded engines

back to the old original type oilpump. The recalibration of

the oilways is carefully adjusted to the higher output of

our better oilpump. The old type oilpump won’t be able

to cope with that, with insufficient lubrication of the whole

engine as a result.

The lower oilscraper groove, beneath

the piston pin, must not be used. This benefits the lubrication

and cooling of the piston skirt. Our modern profiled oilscrapers

are so effective compared to the original design, that lubrication

of the piston and cilinder bore would become inadequate should

a second one be fitted.

In case the excentrical 6 volt dynamo

has to be remounted on the engine it is adviseable to take

off the front engine cover in order to re-adjust the gear

wheel play on the tooth flanges. Make sure the dynamo gear

wheel is on the left, seen towards the front of the engine.

(All mentioned parts are not sold seperately, except for the modified Koni’s

7610 series when available.)

|

|